3M 3015TWF vs. Tremco ExoAir 110AT: A Head-to-Head Comparison of Air & Vapor Barrier Flashing Tapes

Partager

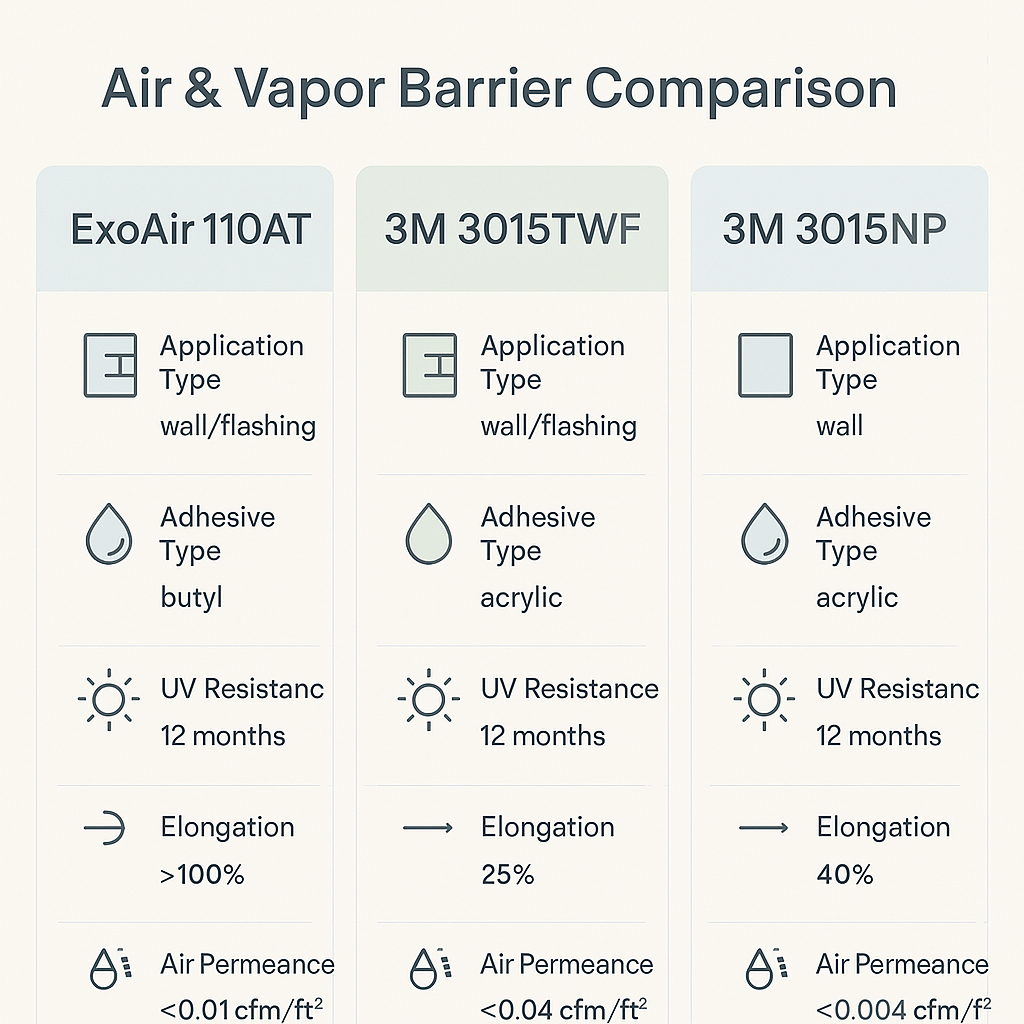

Battle of the Barriers: ExoAir® 110AT vs. 3M™ 3015TWF vs. 3M™ 3015NP

When it comes to protecting buildings from air and moisture infiltration, choosing the right barrier system is critical. Today, we’re comparing three top-tier self-adhered air and vapour barriers: Tremco’s ExoAir® 110AT, 3M™ 3015TWF, and 3M™ 3015NP. Each offers unique strengths, but which one is right for your project?

1. ExoAir® 110AT (Tremco)

Overview:

A high-performance, 18-mil butyl-based membrane with a rugged HDPP facer. Designed for air, vapour, and water resistance in a wide range of substrates.

Pros:

- Primerless application for most surfaces

- Excellent elongation (677%) and tensile strength (2,620 psi)

- High temperature resistance (up to 240°F / 115°C)

- Low air permeance (0.001 L/s·m²) and vapour permeance (0.02 perms)

Cons:

- Not suitable for damp or frost-covered surfaces

- Limited UV exposure (12 months max)

Best For:

Projects requiring high durability, flexibility, and compatibility with a wide range of substrates.

2. 3M™ 3015TWF (Through Wall Flashing)

Overview:

A 15.5-mil-thick, black polyethylene membrane with high-tack acrylic adhesive. Designed specifically for through-wall flashing and damp-proofing.

Pros:

- No primer needed for most surfaces

- Excellent puncture resistance and elongation (>600%)

- Flexible at low temperatures (-30°C)

- UV resistant for up to 12 months

Cons:

- Limited to flashing applications

- Lower tensile strength compared to ExoAir

Best For:

Detailing and flashing applications where flexibility and adhesion are key.

3. 3M™ 3015NP (Air & Vapor Barrier)

Overview:

A semi-translucent, acrylic-based membrane designed for full wall air and vapour barrier applications.

Pros:

- High elongation (700%) and tensile strength (2,150 psi)

- Excellent air permeance (<0.0021 L/s·m²) and vapor transmission

- Wide service temperature range (-40°C to 116°C)

- LEED-compliant and low VOC

Cons:

- Requires careful surface prep and may need primer for difficult substrates

- Slightly thicker (0.25 mm) and heavier than others

Best For:

LEED projects and full-wall applications where sustainability and performance are priorities.

Final Thoughts

| Feature | ExoAir® 110AT | 3M™ 3015TWF | 3M™ 3015NP |

|---|---|---|---|

| Application | Full wall & flashing | Flashing only | Full wall |

| Adhesive Type | Butyl | Acrylic | Acrylic |

| Primer Needed | No (most cases) | No (most cases) | Sometimes |

| UV Resistance | 12 months | 12 months | 12 months |

| Elongation | 677% | >600% | 700% |

| Air Permeance | 0.001 L/s·m² | 0.0013 L/s·m² | <0.0021 L/s·m² |

| Service Temp Range | -6°C to 115°C | -40°C to 80°C | -40°C to 116°C |

Each product excels in different areas. ExoAir 110AT is a robust, all-around performer. 3M 3015TWF is ideal for flashing with excellent flexibility. 3M 3015NP stands out for sustainability and full-wall performance.